Today, the wave of energy internet is sweeping the world. As a key node connecting the power grid and users, smart meters, its accuracy and reliability are directly related to the accuracy of energy metering, the stability of power grid operation and the satisfaction of user services. For energy meter manufacturers, to create a high-precision, high-reliability smart meter, is not only a demonstration of technical strength, but also to win market reputation, build a strong position in the industry's core competitiveness. This paper will deeply analyze the technological breakthroughs and innovative practices of energy meter manufacturers in this field.

First, the core technology breakthrough: from metering chip to algorithm optimization

The technical breakthrough of watt-hour meter manufacturers begins with the ultimate pursuit of metering accuracy. The traditional electric meter is limited by the mechanical structure, and the error is difficult to control. Smart meters through the use of high-precision sensors, digital signal processing chips and advanced algorithms to achieve a qualitative leap in measurement accuracy.

Sensor upgrade: using high-end shunt, the error is controlled within ± 5 ppm, with laser fine-tuning process to achieve 0.01% resistance accuracy; temperature drift is only 0.1 ppm/°C in a wide temperature range, long-term stability is as high as 0.02% , to meet the international measurement standards, to ensure accurate and reliable current sampling.

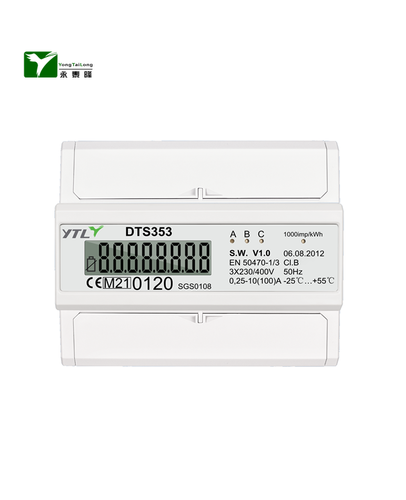

The core of high-precision smart meter is the optimization of metering chip and algorithm. The metering chip is the key to determine the accuracy of the meter. High-quality chips can accurately collect parameters such as current, voltage and power, and the error rate can be as low as ± 0.2%

Algorithm optimization: Wavelet Transform and neural network algorithm are used to deeply filter and correct the sampled data, effectively eliminate harmonic interference, and control the measurement error within 0.2% .

Temperature Compensation: establish a multi-dimensional temperature model, through the accumulation of a large number of data in the laboratory of the electric energy meter manufacturer, realize the automatic calibration of the full temperature zone, ensure that the high precision is maintained at different ambient temperatures.

Second, the reliability of building foundation: to create a“Never down” measurement guardian

In the complex and changeable power grid environment, smart meters need to face severe tests such as lightning strike, surge and electromagnetic interference. Through multi-dimensional design, energy meter manufacturers have built a high-reliability“Iron wall”.

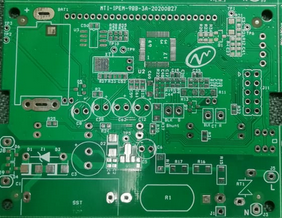

Hardware hardening:

Use industrial grade components, key components are AEC-Q100 certified

Four-layer board design is adopted to enhance anti-interference ability

The redundant design of the key circuit ensures that the single point of failure does not affect the overall operation

Software Protection:

A hardware-grade watchdog is installed to monitor the running status of programs in real time

Develop proprietary operating system to reduce external attack surface

The implementation of data encryption transmission, prevent data tampering

Rigorous testing:

Verify the ultimate performance of the product by HALT (highly accelerated life test)

To simulate various fault scenarios of the power grid and carry out millions of cycle tests

The aging test platform is established to ensure the reliability of the whole life cycle of the product

The electric energy meter manufacturer's smart meter, in the third party test continuous operation 1680 hours without failure, reliability index far beyond the industry standard.

Intelligent Manufacturing: make quality controllable, visual and traceable

To achieve high precision and high reliability of the dual protection, energy meter manufacturers in the manufacturing process under the same full effort. Through intelligent transformation, a transparent and traceable production system is constructed.

Automatic production line: the introduction of SMT high-speed placement machine, Aoi optical detector and other equipment, the key process automation rate of 95% , reduce human interference.

Quality access control system: detection nodes are set up in each process, quality early warning is realized through big data analysis, and unqualified products are automatically intercepted.

Traceability system: establish product life cycle archives, from components procurement to user installation, every link can be traced to ensure accurate recall of defective products.

Iv. Innovation-driven: continuing to break through the technology ceiling

Facing the new demand of energy transformation, energy meter manufacturers continue to increase investment in research and development, and explore the application of new technologies in the field of smart meters.

Application of new materials: Research and development of graphene-based sensors to improve temperature stability and sensitivity.

Edge Computing: deploy AI algorithms at the meter end to achieve local anomaly detection and early warning.

Quantum metrology: Explore the application of quantum sensing technology in high-precision metrology, and reserve power for future technology upgrading.

Customer Witness: The Market is the touchstone

Ultimately, the value of a product needs to be measured by the market. Many electric energy meter manufacturers through high precision, high reliability of smart meters, won the trust of customers.

In the smart grid transformation of a European country, a meter manufacturer's product has a measurement accuracy of 0.1% , which helps the power grid enterprise to improve the rate of electricity recovery by 2% .

In the Smart City project, the line loss rate is reduced from 6% to 2.8% through the smart meter of the energy meter manufacturer to achieve accurate monitoring of the line loss in the station area.

In Southeast Asia, Africa and other countries to adopt anti-theft smart meters, effectively curb illegal electricity behavior, reducing annual losses of more than 10 million yuan.

Vi. Future Outlook: jointly build a new ecology of intelligent metrology

Facing the future, energy meter manufacturers will continue to adhere to technological innovation and ecological co-construction. On the one hand, deepen cooperation with power grid companies and energy service providers to jointly develop industry standards; on the other hand, explore the new role of smart meters in the energy internet, for example, as a distributed energy access point and a carbon footprint metering terminal.

It can be predicted that with the deepening of the energy revolution, electric energy meter manufacturers will not only be the providers of metering equipment, but also the enablers of the digital transformation of energy. Those who continue to deep technology, adhere to the quality of meter manufacturers, will be in the field of smart meters to write a new legend.

In this era when accuracy determines value and reliability wins the market, energy meter manufacturers are polishing each smart meter with the spirit of Craftsman, guarding the safety of energy measurement with the power of science and technology, and industrial upgrading with innovation.

English

English 中文简体

中文简体

.jpg?imageView2/2/w/500/h/500/format/png/q/100)