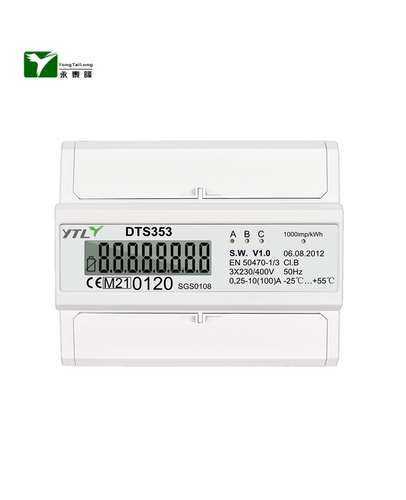

Modbus energy meter ,which is widely used in the field of power metering. Residential users, industrial automation, equipment (such as EV chargers), photovoltaic power generation and building energy conservation have a large number of applications. Energy meter manufacturers will design a variety of different shapes and functions of Modbus energy meter to meet market demand according to different application scenarios.

Modbus energy meter ,which is widely used in the field of power metering. Residential users, industrial automation, equipment (such as EV chargers), photovoltaic power generation and building energy conservation have a large number of applications. Energy meter manufacturers will design a variety of different shapes and functions of Modbus energy meter to meet market demand according to different application scenarios.

When developing a Modbus energy meter, the following points should be noted:

1. Determine the type of Modbus energy meter protocol: according to the application requirements and characteristics of the equipment, choose the suitable Modbus protocol type, such as Modbus TCP, Modbus RTU or Modbus ASCII, etc. In the Modbus energy meter, the Modbus RTU protocol is the most commonly used.

2. Choose the appropriate communication method for the Modbus energy meter: according to the equipment and application scenario, choose the appropriate communication method, such as RS-485, Ethernet, wireless, etc.

3. Consider the communication rate of the Modbus energy meter: according to actual needs, select the appropriate communication rate to ensure the real-time and accuracy of data transmission; 1200bps, 2400bps, 9600bps, 19200bps, 115200bps, etc.

4. Determine the data transmission format of the Modbus energy meter. The Modbus protocol specifies the format of data transmission, including data start code, data length, data content, check code, etc. When designing, it is necessary to determine the data transmission format according to actual needs.

5. Consider Modbus energy meter data storage and backup: For systems that require long-term monitoring of energy data, it is necessary to consider data storage and backup methods to avoid data loss or damage.

6.Ensure the security of Modbus energy meter data: When designing, consider data security and take encryption measures and other security measures to protect the confidentiality and integrity of data.

7. Consider the scalability and compatibility of Modbus energy meter when designing. Think about future system expansion and upgrades, as well as compatibility with other devices.

8. Optimize the hardware and software design of Modbus energy meter: Optimize the hardware and software design based on actual needs and application scenarios to improve the performance and efficiency of the system.

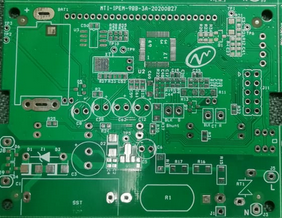

When developing and designing the Modbus energy meter, safety considerations should be taken into account during installation and operation. For high-voltage parts, isolation design is required. The communication interface of the Modbus energy meter is isolated from the power supply for safety reasons. This isolation technology can prevent power failures from affecting the communication interface, ensuring the safe and stable operation of the energy meter.

Modbus energy meter communication interface and power supply safety isolation usually use the following technologies:

Modbus energy meter communication interface and power supply safety isolation usually use the following technologies:

1. Isolated power supply: The communication interface of the energy meter is isolated from the power supply to prevent power failure from affecting the communication interface. For example, an isolated power supply module can be used to isolate the communication interface from the main power supply of the energy meter.

2. Photoelectric isolation: Through photoelectric coupling devices such as isolators, the communication interface of the energy meter is isolated from the power supply to prevent power failure from affecting the communication interface. This isolation method can effectively isolate the electrical connection between the power supply and the communication interface.

3. Digital isolation: Using digital signal isolators, the communication interface of the energy meter is isolated from the power supply to prevent power failure from affecting the communication interface. This isolation method can effectively isolate the digital signal connection between the power supply and the communication interface.

The communication interface between the Modbus energy meter and the power supply safety isolation is one of the important measures to protect the safety of the energy meter. By using a combination of various technologies, it is possible to effectively prevent power failure from affecting the communication interface, ensuring the safe and stable operation of the energy meter. Only by clearly defining the real functional and application requirements of the market in research and development design, considering the product's safety and adaptability, can we meet the needs of the market and provide value for users.

English

English 中文简体

中文简体

.jpg?imageView2/2/w/500/h/500/format/png/q/100)

.jpg?imageView2/2/w/500/h/500/format/png/q/100)

.jpg?imageView2/2/w/500/h/500/format/png/q/100)