Blog

Home / Information Activity / Blog / How Do Harsh Environmental Conditions Impact the Accuracy of DC Energy Meters?

How Do Harsh Environmental Conditions Impact the Accuracy of DC Energy Meters?

The accuracy of DC energy meters is paramount for effective energy management and billing, making it crucial to understand how harsh environmental conditions can impact this key aspect. Here's a more detailed exploration of how various factors can affect the accuracy of these meters:

Temperature Fluctuations:

Temperature changes, especially in extreme environments, can lead to thermal drift in DC energy meters. Thermal drift occurs when the internal temperature of the meter differs from the temperature at which it was calibrated. This drift can cause the meter to provide readings that deviate from the actual energy flow. For example, in a solar power system, if the meter experiences a significant temperature increase, it might register higher energy production than what is actually occurring.

Humidity and Moisture:

High humidity levels and moisture exposure pose significant risks to the accuracy of DC energy meters. Moisture can lead to corrosion of internal components, affecting the meter's ability to measure current and voltage accurately. Condensation inside the meter can also create electrical shorts or interfere with the functioning of sensitive electronics, leading to erratic readings.

Dust and Debris Accumulation:

In outdoor environments or industrial settings, dust, dirt, and debris can accumulate on the sensors and circuitry of DC energy meters. This accumulation can create a barrier between the sensors and the electrical currents they are measuring, resulting in inaccurate readings. Additionally, dust can cover optical sensors or obstruct airflow in cooling systems, affecting the overall performance of the meter.

Corrosive Elements:

Certain environments, such as coastal areas with salty air or industrial locations with chemical exposure, can introduce corrosive elements. Corrosion on connectors, wiring, or circuit boards can degrade the electrical connections, leading to resistance and voltage drops. This corrosion can introduce errors in the measurement of voltage and current, impacting the overall accuracy of the meter.

Long-Term Performance Degradation:

Continuous exposure to harsh environmental conditions can lead to the gradual degradation of meter components. Over time, the accuracy of the meter may diminish as components wear out or become damaged by the environment. This can result in a gradual drift in readings, making it challenging to rely on the meter for precise energy measurements.

Addressing Accuracy Challenges:

To mitigate the impact of these factors on the accuracy of DC energy meters, manufacturers and users can take several steps:

Calibration and Periodic Maintenance:

Regular calibration of DC energy meters is essential to ensure accurate readings, especially after exposure to extreme conditions. Periodic maintenance checks can identify and address any issues related to temperature drift, sensor contamination, or corrosion.

Sealed and Ruggedized Design:

Using meters with sealed, weatherproof enclosures can protect sensitive components from moisture, dust, and debris. Ruggedized designs are more resistant to the effects of temperature variations and mechanical stress, preserving accuracy in harsh environments.

Temperature Compensation Algorithms:

Advanced DC energy meters often incorporate temperature compensation algorithms. These algorithms adjust the meter readings based on the ambient temperature, minimizing the impact of thermal drift on accuracy.

Remote Monitoring and Diagnostics:

Implementing remote monitoring capabilities allows users to track the performance of DC energy meters in real-time. Any deviations from expected readings can trigger alerts, enabling prompt investigation and maintenance.

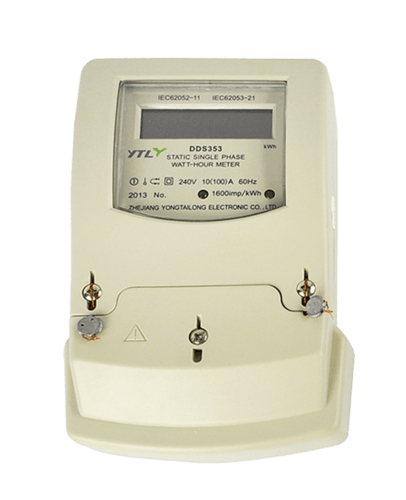

YTL is a professional supplier of energy meter and AMI solution. the Top 100-enterprise with most investment value in Zhejiang. And“Yongtailong”is the famous brand of Zhejiang. With nearly 20 years' experience in energy metering, we devote ourselves to providing competitive projects and creating value for customers.

● Online + Offline. Provide cost-effectiv solutions

● Strict quality control mechanism.High quality assurance

● Five R&D centers,combine with hardware&software design, experiment and testing

● Global service capability, provide customers timely and effective solution

● Good customer feedback. Reliable after-sales service

● Online + Offline. Provide cost-effectiv solutions

● Strict quality control mechanism.High quality assurance

● Five R&D centers,combine with hardware&software design, experiment and testing

● Global service capability, provide customers timely and effective solution

● Good customer feedback. Reliable after-sales service

-

- ABOUT YTL

- About YTL

- Factory

- Honor

- Development

- Privacy

-

- YTL culture

- Culture

- Values

- Advantage

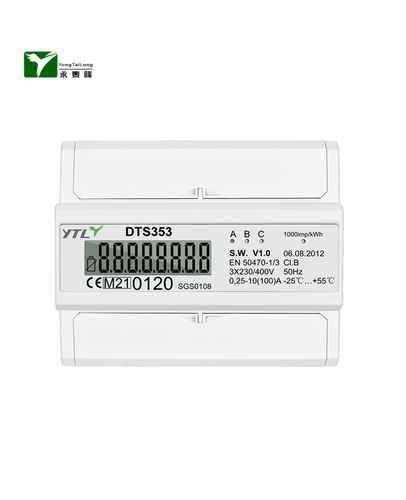

- Three Phase kWh Meter

-

- products

- Single Phase Din Rail Meter

- Three Phase Smart APS Electric Energy Meters

- Three Phase Multi Function Electronic Energy Meter

- Digital Electric Meters

- Electronic Energy Meter

- Electronic Energy Meters

- Three Phase Keypad split type Energy Meter

- Single Phase IC Card Prepayment Energy Meters

- Three Phase Anti-tamper Suspension Energy Meters

-

- Information Activity

- Exhibition News

- Blog

- Staff Activity

- Single Phase Smart Watt Hour Meter

COPYRIGHT © 2020 Zhejiang Yongtailong Electronic Co., Ltd. ALL RIGHTS RESERVED .  China Electronic Energy Meters Manufacturers

China Electronic Energy Meters Manufacturers

English

English 中文简体

中文简体.png?imageView2/2/w/500/h/500/format/png/q/100)

.jpg?imageView2/2/w/500/h/500/format/png/q/100)