In the pre-installation preparation stage, it is necessary to ensure that the meter body and supporting equipment have complete certification marks. Products that have not been tested by professional organizations or have physical damage are prohibited from being put into use. The selection of the installation location needs to comprehensively consider the environmental stability. Priority should be given to areas with good ventilation, away from strong electromagnetic interference and convenient for daily maintenance. At the same time, ensure that the meter box is kept at a safe distance from the surrounding equipment to avoid inaccurate measurement due to abnormal environmental temperature and humidity or mechanical vibration. For installation carriers made of special materials, standardized insulation isolation measures must be taken, and potential static electricity or leakage risks must be eliminated through a reliable grounding system.

Standardized implementation of wiring technology is the core link to ensure safety. Operators must strictly perform phase matching in accordance with the product technical manual, use wire cross-sectional areas and connection processes that meet industry standards, and focus on preventing hidden dangers such as wire burrs, virtual connections or metal fatigue. When using mutual inductors, the compatibility of supporting equipment must be ensured, and the wiring of the secondary circuit must be physically isolated to avoid signal crosstalk affecting the measurement accuracy. All metal components should form a complete protection circuit through professional equipotential connection technology, and perform multi-dimensional insulation tests after wiring is completed.

The operation protection system needs to build multiple safety guarantee mechanisms. It is recommended to configure an adaptive circuit breaker protection device on the power input side and verify the response sensitivity of the protection function during the commissioning phase. The communication module of the smart meter needs to enable the anti-tampering protocol and implement encryption and lock on the key parameter configuration. The lead seal management system should adopt graded anti-counterfeiting technology, and establish traceable closed-loop management at every link from factory to acceptance. For abnormal working conditions, the built-in intelligent diagnosis system of the meter will actively prompt the risk through the preset alarm mechanism. At this time, the operation needs to be interrupted immediately and the troubleshooting process needs to be started.

At the later operation and maintenance level, it is recommended that users establish a periodic preventive maintenance system, focusing on monitoring the contact status of the terminal block and environmental adaptability indicators. Cleaning and maintenance require the use of designated solvents to avoid chemical corrosion affecting electrical performance. When the equipment reaches the designed service life or irreversible performance degradation occurs, the original accessories must be replaced through formal channels, and cross-brand mixing of components is strictly prohibited. We recommend the use of a digital operation and maintenance platform to achieve remote status monitoring and avoid potential risks in advance through abnormal data warnings.

It should be noted that the reliable operation of the meter not only depends on the quality of the product itself, but is also closely related to the standardization of the installation operation. We always recommend that installation be carried out by a professionally qualified team, and through a dual-track parallel mode of standardized training and remote technical support, ensure that every operation detail complies with safety regulations. When encountering special working conditions or uncertain factors, please be sure to suspend the operation and contact the technical team in time for collaborative processing. Do not blindly operate based on experience.

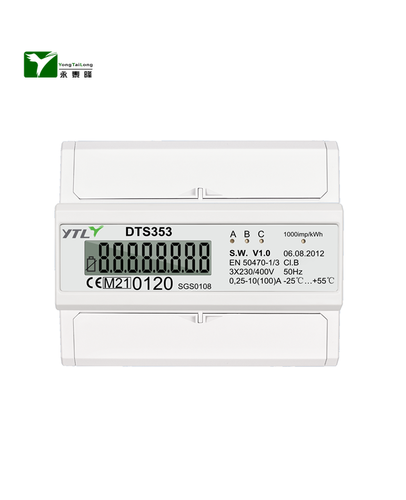

Choosing our three-phase meter is not only choosing a metering device, but also injecting reliable protection and smart genes into your power system. We use craftsmanship to cast the core of each meter, and through rigorous factory inspection and full life cycle service system, we accurately protect your power safety and energy efficiency value. Whether it is complex load management in industrial scenarios or innovative needs in the field of new energy, our professional team always responds to challenges with customized solutions.

English

English 中文简体

中文简体

.jpg?imageView2/2/w/500/h/500/format/png/q/100)