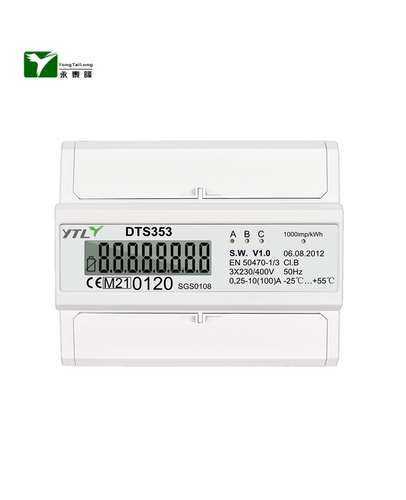

8 Parts of Electric Energy Meter

An electric energy meter is an instrument used to measure electrical energy, which is also known as a kilowatt-hour meter or electricity meter. Its unit of measurement is the degree or kilowatt-hour. It is a product of power and time and can be used to measure the power consumption of end users, serving as the basis for billing by electric companies. Electricity is an indispensable energy source in people's daily lives, and electric energy meters are installed in every household. However, most users are not familiar with the working principles, structure, and components of electric energy meters.

Based on the working design principles of electric energy meter, they can generally be divided into eight modules: the power supply module, the display module, the storage module, the sampling module, the measuring module, the communication module, the control module, and the MUC processing module. Each module has its own function and is coordinated and integrated by the MUC processing module, forming a whole.

1. Electric Energy Meter Power Supply Module

The power supply module of the electric energy meter serves as the energy center for its normal operation. The main function of the power supply module is to convert the high voltage of AC 220V into DC 12V/DC5V/DC3V. 3V low voltage power is provided to chips and devices of other modules within the electric energy meter. There are three common types of power supply modules: the transformer, the resistor-capacitor voltage reduction module, and the switch power supply.

The transformer type converts the AC 220V power supply into AC12V, and then proceeds with rectification, voltage reduction, and stabilization to achieve the required voltage range. It has a small power capacity, high stability, but it is easily affected by electromagnetic interference.

The resistor-capacitor voltage reduction power supply circuit utilizes the capacitive reactance produced by the capacitor at a specific frequency of the AC signal to restrict the maximum operating current. It is small in size, low in cost, consumes little power, and has a high level of self-consumption.

The switch-mode power supply uses electronic switching devices such as transistors, MOS tubes, SCRs, etc. To periodically turn on and off the electronic switching devices via control circuits, allowing them to modulate the input voltage in pulses, thereby achieving voltage transformation while simultaneously providing an adjustable and automatically stabilized output voltage. It has a low power consumption, is small in size, has a wide voltage stabilization range, experiences high-frequency interference, and has a higher price.

In the development and design of electric energy meters, the choice of power supply type is determined based on product functional requirements, meter terminal cover dimension, cost control requirements, and policies and regulations of different regions or countries.

2. Electric Energy Meter Display Module

The electric energy meter display module is primarily used for reading power consumption and offers various display options such as digital tubes, counters, standard LCDs, dot matrix LCDs, and touch LCDs, among others. The display methods of digital tubes and counters can only show electrical consumption in one way. With the development of the smart grid, electric energy meters require an increasing number of types of power data displays. Digital tubes and counters are unable to meet the demands of modern power intelligence. The primary display method for electric energy meters at present is LCD technology. Different types of LCDs are chosen during the research and development process depending on the complexity of the information being presented.

3. Electric Energy Meter Storage Module

The electric energy meter storage module is primarily used for storing meter parameters, power consumption history, and other relevant information. Common storage devices include EEPROM chips, ferroelectric chips, and flash chips. These three types of chips have different applications in electric energy meters. Flash is a type of flash memory that stores temporary data, load profile data, software upgrade packages, etc.

EEPROM is an electrically erasable programmable read-only memory that allows users to erase and reprogram the information stored in it using either the device itself or dedicated devices. This makes EEPROM very useful in scenarios requiring frequent modifications and updates to the data. EEPROM can store up to 1 million bytes of information and is used in electric energy meters to store power consumption and other power-related data. The number of storages available meets the storage requirements for the entire lifecycle of an electric energy meter, and they are reasonably priced.

Ferroelectric chips utilize the characteristics of ferroelectric materials to achieve high-speed, low-power, and highly reliable data storage and logical operations. They have a storage capacity of one billion times. The data will not be cleared after a power failure, making ferroelectric chips advantageous due to their high storage density, fast speed, and low energy consumption. Ferroelectric chips are primarily used in electric energy meters for storing power consumption and other related data. They have a higher price and are only used in products that require high-frequency storage needs.

4. Electric Energy Meter Sampling Module

The electric energy meter sampling module is responsible for converting large current signals and large voltage signals into small current signals and small voltage signals for easy acquisition by the electric energy meter. Common current sampling devices include shunts, current transformers, and Rogowski coils. Voltage sampling is typically performed using a high-precision resistor voltage divider sampling method.

5. Electric Energy Meter Measurement Module

The electric energy meter measurement module is primarily utilized for acquiring analog current and voltage signals and converting them into digital signals. It can be divided into a single-phase measurement module and a three-phase measurement module.

6. Electric Energy Meter Communication Module

The electric energy meter Communication Module serves as the foundation for data transmission and interaction, acting as a basis for scientific management of the smart grid, data digitization, intelligence, and accuracy. It is also the foundation for enabling human-computer interaction in the development of the Internet of Things. In the past, the primary means of communication were infrared and RS-485 communication. With the development of communication technology and the Internet of Things (IoT), the selection of electric energy meter communication methods has become extensive. These include PLC, RF, RS485, LoRa, ZigBee, GPRS, NB-IoT, and more. Different communication methods can be chosen based on their advantages and disadvantages, as well as the specific application scenarios, to meet market demands.

7. Electric Energy Meter Control Module

The electric energy meter control module enables effective control and management of the electrical load. The most common method is to install a magnetic latching relay inside the electric energy meter. The control and management of electrical loads can be achieved using power data, control schemes, and real-time commands for turning power on or off. Common functions in a electric energy meter include overcurrent and overload protection through relay disconnection to control the load, time-based control for turning power on or off during specific time periods, relay disconnection when the credit is insufficient in prepaid functionality, and remote control via real-time command transmission.

8. Electric Energy Meter MCU Processing Module

The Electric Energy Meter's MCU Processing Module is the brain of the electric energy meter. It performs calculations on various types of data, converts and executes various types of instructions, and coordinates the various modules to successfully implement the functions.

An electric energy meter is a complex electronic measuring device that includes several aspects of electronic technology, including power supply technology, power measurement technology, communication technology, display technology, and storage technology. Each functional module and electronic technology needs to be integrated and combined to form a complete unit in order to create a stable, reliable, and accurate electricity meter.

English

English 中文简体

中文简体

.jpg?imageView2/2/w/500/h/500/format/png/q/100)

.png?imageView2/2/w/500/h/500/format/png/q/100)