Blog

Home / Information Activity / Blog / In What Ways Do Residential and Industrial Electric Meters Diverge?

In What Ways Do Residential and Industrial Electric Meters Diverge?

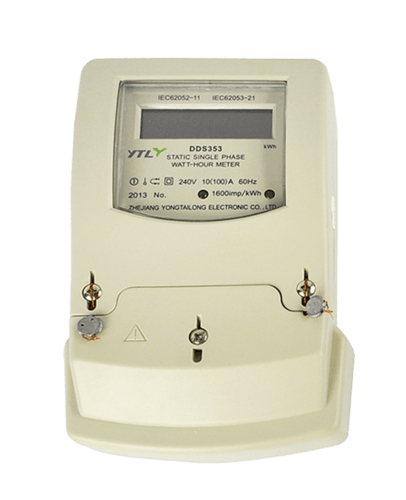

Residential Meters: Designed for lower capacity needs, residential meters typically handle the electricity demands of individual households. They are calibrated to measure power consumption within the range typically required for homes.

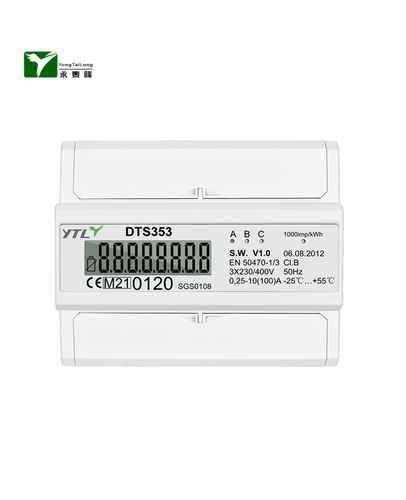

Industrial Meters: These meters are built to accommodate substantially higher energy requirements found in factories, warehouses, and large-scale manufacturing units. They can handle heavy loads associated with industrial machinery and equipment.

2. Voltage Requirements:

Residential Meters: Tailored for standard voltage levels prevalent in residential areas. They accurately measure power consumption within this typical range.

Industrial Meters: Configured to handle higher voltage levels, as industrial settings may require more powerful electrical systems. These meters are designed to accurately gauge usage in environments with elevated voltage demands.

3. Tariff Structures:

Residential Meters: Residential tariffs often include fixed charges and progressive tariffs based on usage patterns. This structure aligns with the predictable daily energy consumption of households.

Industrial Electric Meters: Tariffs for industrial meters are more complex, incorporating demand charges, time-of-use tariffs, and other customized pricing models. This reflects the varied and often dynamic energy usage patterns in industrial facilities.

4. Demand Characteristics:

Residential Meters: Residential power demand typically follows a predictable daily pattern, with peak usage in the evenings when occupants return home. Meters are calibrated to handle this routine.

Industrial Meters: Industrial facilities may experience fluctuating demand throughout the day based on production cycles. Industrial meters are equipped to handle a more dynamic load profile, capturing the variability inherent in manufacturing operations.

5. Monitoring and Control Features:

Residential Meters: Often standalone units with basic monitoring features. They provide essential information but lack the advanced capabilities required for large-scale energy management.

Industrial Meters: Equipped with advanced monitoring and control features. These meters allow real-time management of complex energy systems, providing industrial operators with tools to optimize energy usage, identify inefficiencies, and respond promptly to changing conditions.

6. Communication Protocols:

Residential Meters: Typically designed as standalone devices, communicating usage data to utility providers for billing purposes.

Industrial Meters: Integrated into broader energy management systems. They support various communication protocols, such as Modbus or DNP3, enabling seamless integration with SCADA systems. This integration facilitates comprehensive monitoring and control of energy systems in industrial settings.

7. Environmental Considerations:

Residential Meters: Built to withstand the more controlled conditions of home installations. They are not exposed to extreme environmental conditions.

Industrial Meters: Designed to endure harsh industrial environments, including extreme temperatures, high humidity, and potential exposure to dust and chemicals. Industrial meters are ruggedized to ensure reliable operation in challenging conditions commonly found in manufacturing facilities.

YTL is a professional supplier of energy meter and AMI solution. the Top 100-enterprise with most investment value in Zhejiang. And“Yongtailong”is the famous brand of Zhejiang. With nearly 20 years' experience in energy metering, we devote ourselves to providing competitive projects and creating value for customers.

● Online + Offline. Provide cost-effectiv solutions

● Strict quality control mechanism.High quality assurance

● Five R&D centers,combine with hardware&software design, experiment and testing

● Global service capability, provide customers timely and effective solution

● Good customer feedback. Reliable after-sales service

● Online + Offline. Provide cost-effectiv solutions

● Strict quality control mechanism.High quality assurance

● Five R&D centers,combine with hardware&software design, experiment and testing

● Global service capability, provide customers timely and effective solution

● Good customer feedback. Reliable after-sales service

-

- ABOUT YTL

- About YTL

- Factory

- Honor

- Development

- Privacy

-

- YTL culture

- Culture

- Values

- Advantage

- Three Phase kWh Meter

-

- products

- Single Phase Din Rail Meter

- Three Phase Smart APS Electric Energy Meters

- Three Phase Multi Function Electronic Energy Meter

- Digital Electric Meters

- Electronic Energy Meter

- Electronic Energy Meters

- Three Phase Keypad split type Energy Meter

- Single Phase IC Card Prepayment Energy Meters

- Three Phase Anti-tamper Suspension Energy Meters

-

- Information Activity

- Exhibition News

- Blog

- Staff Activity

- Single Phase Smart Watt Hour Meter

COPYRIGHT © 2020 Zhejiang Yongtailong Electronic Co., Ltd. ALL RIGHTS RESERVED .  China Electronic Energy Meters Manufacturers

China Electronic Energy Meters Manufacturers

English

English 中文简体

中文简体

.jpg?imageView2/2/w/500/h/500/format/png/q/100)

.jpg?imageView2/2/w/500/h/500/format/png/q/100)