Make your device speak

In the production and operation activities of a company, equipment management is a guarantee for the production of the company. Only by implementing the management policy of "pay equal attention to maintenance and repair, and put prevention first ", ensuring the normal operation of equipment, reducing failures, eliminating accidents and improving production efficiency can make enterprises achieve the highest economic benefits. Enterprises invest a lot of money to buy dozens or even hundreds of equipment. These machines are the most important things for enterprises. How to maintain the machines so that they can operate efficiently? How to promptly alarm the abnormal situation of the equipment and quickly locate the abnormal position? How to monitor the power safety of equipment 24 hours a day? It is a problem for every enterprise. At present, only regular maintenance and fault shutdown maintenance can be achieved, which affects the normal production and operation of the enterprise. Therefore, enterprises need more professional and safer equipment that integrates monitoring, prediction, and management to run monitoring products in real time.

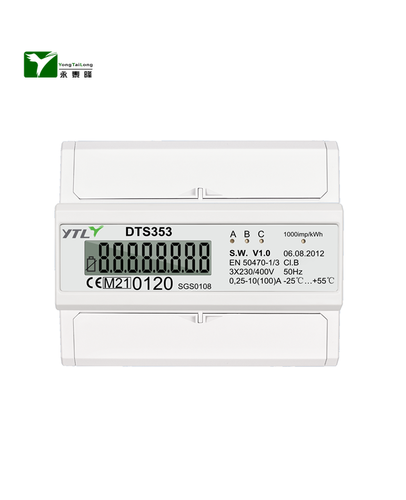

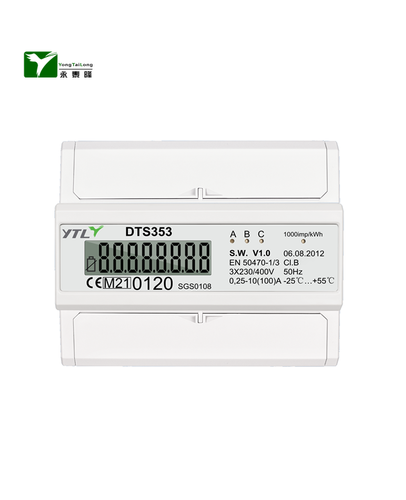

YTL smart power sensor system integrates information collection, real-time monitoring, analysis and prediction, safety alarm, energy consumption monitoring and remote management and control. It can be widely used in the management of various electrical appliances, electromechanical equipment, and can effectively achieve remote interconnection and safety prevention and control, fault prediction, preventive maintenance, energy saving and consumption reduction.

Smart power sensor system function introduction

System functions:

- Prevent electrical fires and protect personal and property safety

Safety alarm: abnormal over-current, over-voltage and over-voltage, excessive leakage current of equipment, over-temperature of load wire or some components; real-time alarm

- Scientific management of electricity consumption to achieve energy saving and consumption reduction

Energy consumption monitoring: real-time monitoring of energy consumption, efficiency parameters such as power, active power, reactive power, power factor of various equipment;

- Predictive maintenance, reduce failure rate and extend equipment life cycle

Real-time monitoring: 24-hour real-time acquisition and monitoring of the starting current waveform, periodic current waveform, and harmonic components of equipment operation; storage and analysis of waveform data to realize fault diagnosis and predict the operating status of the unit; if abnormal, send warning information to the relevant person.

Failure alarm: real-time alarm of equipment failure and multiple notification methods to reach the user as soon as possible to avoid outages and equipment damage.

- Smart joint control management to reduce labor costs

Intelligent monitoring: online connection, real-time online monitoring of data, remote setting of device parameter values, improve work efficiency and save labor;

The equipment is connected to the cloud platform through intelligent power sensors, collects operating data in real time, remotely monitors and diagnoses, predicts equipment failure in advance, and makes predictive maintenance work; effectively realizes the device Internet of Things. For the device with a processing module or PLC, the data of the intelligent power sensor can be read and applied through RS485. Increasing small costs to enhance the added value of equipment and improve its competitiveness. It extends from the "equipment trading" to "intelligent service" in one transaction to generate a source of continuous profits and prompt the Industrial Internet of Things. Realize the upgrade from the Internet-Internet of Things-intelligent manufacturing from the perspective of equipment management. If you are an operation and maintenance service provider, it will help provide better after-sales service and obtain better service income!

English

English 中文简体

中文简体

.jpg?imageView2/2/w/500/h/500/format/png/q/100)