Pulse energy meters have high power measurement accuracy and are simple to install and operate. They are the most widely used electric energy meters for measuring electric energy consumption. As the market has higher and higher requirements for power measurement and the differences in installation application scenarios, personalized needs and customized requirements are also emerging. Pulse energy meters have also made many extensions in terms of functions, such as electricity tamper prevention, cover opening detection, backflow prevention, etc.. in terms of appearance, there are din rail type, hanging type, panel type, round type, etc.. in terms of performance, they closely follow the standard requirements. improvement.

Pulse energy meters have high power measurement accuracy and are simple to install and operate. They are the most widely used electric energy meters for measuring electric energy consumption. As the market has higher and higher requirements for power measurement and the differences in installation application scenarios, personalized needs and customized requirements are also emerging. Pulse energy meters have also made many extensions in terms of functions, such as electricity tamper prevention, cover opening detection, backflow prevention, etc.. in terms of appearance, there are din rail type, hanging type, panel type, round type, etc.. in terms of performance, they closely follow the standard requirements. improvement.

In the IEC standard, EN standard, Q/GDW standard and other electric energy meter standards, there are clear requirements for the pulse output form and output parameters of pulse energy meters. the unified pulse output interface standard is conducive to the compatibility and universality of collection devices and detection equipment. stability and interoperability. it improves the standardization level of pulse energy meters and is conducive to the wider development and application of pulse energy meters.

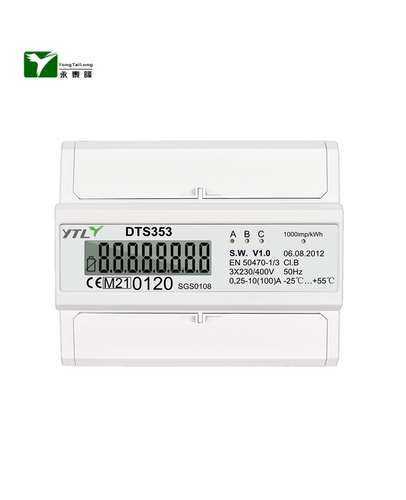

Pulse energy meters must have optical test output. The location and indicators of the optical output are clearly stated in the standard. The pulse output of the pulse energy meter must be directly in front, so that the user can see it. The test output pulses should represent the total energy measured by the meter on all phases of the electrical system. The optical test output should produce a number of pulses proportional to the measured energy, which we call the pulse constant. Pulse outputs generally do not produce periodic pulses. Therefore, the manufacturer should state the necessary number of pulses to ensure that the measurement accuracy at different test points is at least ±1/10 of the instrument grade. The wavelength of the radiation signal output by the optical test should be between 550 nm ~ 1000 nm, and the maximum pulse frequency should not exceed 2.5 kHz. In daily use, people can judge the size of the electrical load in the home based on the flashing speed of the optical pulse of the pulse energy meter (i.e., the pulse indicator light). the faster the flashing frequency of the pulse indicator light, the greater the electrical load in the home.

Pulse energy meters must have optical test output. The location and indicators of the optical output are clearly stated in the standard. The pulse output of the pulse energy meter must be directly in front, so that the user can see it. The test output pulses should represent the total energy measured by the meter on all phases of the electrical system. The optical test output should produce a number of pulses proportional to the measured energy, which we call the pulse constant. Pulse outputs generally do not produce periodic pulses. Therefore, the manufacturer should state the necessary number of pulses to ensure that the measurement accuracy at different test points is at least ±1/10 of the instrument grade. The wavelength of the radiation signal output by the optical test should be between 550 nm ~ 1000 nm, and the maximum pulse frequency should not exceed 2.5 kHz. In daily use, people can judge the size of the electrical load in the home based on the flashing speed of the optical pulse of the pulse energy meter (i.e., the pulse indicator light). the faster the flashing frequency of the pulse indicator light, the greater the electrical load in the home.

The pulse energy meter must have a pulse output interface, and the output form is square wave. The standard requires that the pulse output width is 80ms±16ms. when there is pulse output, the voltage drop of the pulse output port when passing 5mA current shall not be higher than 0.8V. when there is no pulse output, the DC impedance of the pulse output port shall not be less than 100kΩ . For a pulse energy meter with accuracy class 1, the maximum voltage of the pulse output is DC15V. When the square wave pulse is high level, the current range is between 2mA and 15mA. When the pulse output is low level, the current must be less than 0.15mA.

The optical test output and pulse interface output of the pulse energy meter play a very important role. The number of pulse outputs is proportional to the amount of electricity, that is, the pulse constant. For example, the nameplate of a pulse energy meter is marked with 1000imp/kWh. This means that the pulse indicator light flashes 1000 times to represent 1 kilowatt hour of electricity, and the pulse interface outputs 1000 pulses to represent 1 kilowatt hour of electricity. Both the pulse indicator light and the pulse output interface can be connected to the sampling interface of the accuracy calibration device for comparative sampling of pulse energy meters during manufacturing. The pulse interface is connected to the pulse collector, and according to the characteristics of the pulse constant, the number of pulses is converted into electricity for storage and transmission through other communication methods to complete the upgrade and transformation of remote data collection.

The optical test output and pulse interface output of the pulse energy meter play a very important role. The number of pulse outputs is proportional to the amount of electricity, that is, the pulse constant. For example, the nameplate of a pulse energy meter is marked with 1000imp/kWh. This means that the pulse indicator light flashes 1000 times to represent 1 kilowatt hour of electricity, and the pulse interface outputs 1000 pulses to represent 1 kilowatt hour of electricity. Both the pulse indicator light and the pulse output interface can be connected to the sampling interface of the accuracy calibration device for comparative sampling of pulse energy meters during manufacturing. The pulse interface is connected to the pulse collector, and according to the characteristics of the pulse constant, the number of pulses is converted into electricity for storage and transmission through other communication methods to complete the upgrade and transformation of remote data collection.

Pulse energy meters are used in residential homes, industrial factories, shopping malls and other scenarios. They have a long history and follow the development needs of the power market through continuous iteration of product functionality. The pulse energy meter is responsible for the measurement and storage of raw electric energy and is one of the basic equipment for power grid data collection. Through the remote transmission of power data, it is the basis for data integration, analysis, optimization and data display.

English

English 简体中文

简体中文

.png?imageView2/2/w/500/h/500/format/png/q/100)

.png?imageView2/2/w/500/h/500/format/png/q/100)

.png?imageView2/2/w/500/h/500/format/png/q/100)

.png?imageView2/2/w/500/h/500/format/png/q/100)