With the development of science and technology, well-known American companies Itron and Swiss L&G have transformed their production lines into automated production lines.

At the same time, YTL Metering realized that only by keeping pace with the times and constantly improving skills and knowledge, can we not be out of touch with the times and maintain a certain degree of competitiveness.

If the ordinary electric meter production line is upgraded to an automated production line, it will be great advantages.

However, what kind of production line could be called smart meter automated production line?

- There is a high degree of automation, and the flow operation does not need to be manually transported, and there is no need to manually disassemble or wire, which improves labor productivity and reduces labor intensity.

- There is a strict production rhythm to speed up the production process and reduce product costs.

- There is a unified control system to realize the computer tracking of the whole process, and the status of each electric meter is tracked from the beginning of the order to each process, so as to realize the traceability of the whole production process.

- Reduce the influence of human factors in the production process, improve the product straight-through rate, and ensure and improve product quality.

- Conducive to large-scale mass production.

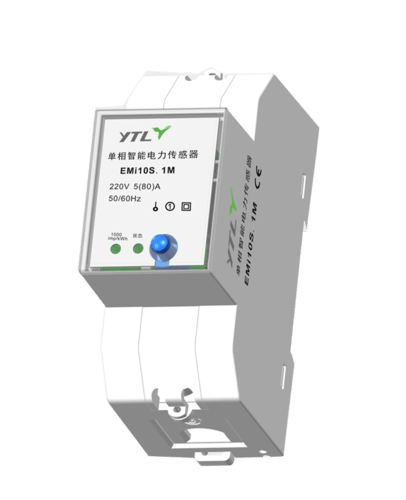

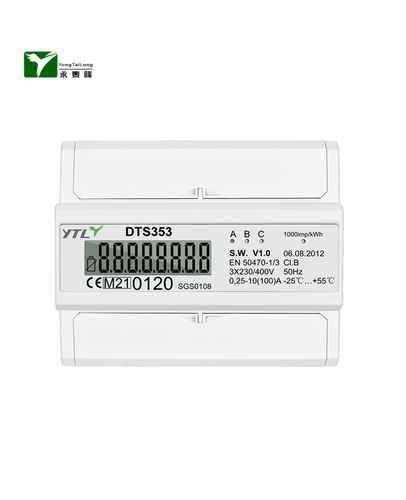

YTL Metering has automated production line, could produce 8,000,000 electric meters per year, already formed bulk production. Entire production process of each meter can be traced, and product through rate is very high.

From the picture, we can see that YTL Metering ’s average product through rate is as high as 99.8%!

If you wanna to know more about YTL Metering, Welcome to contact us!

English

English 中文简体

中文简体

.jpg?imageView2/2/w/500/h/500/format/png/q/100)