With the development of artificial intelligence technology, more and more new things have emerged-smart cities, Internet of Things, VR intelligence, autonomous driving, etc. Recently, the concept of the Internet of Things has become clearer, and the Internet of Things technology will inevitably be widely used in enterprise equipment management in the future. Many current enterprises have encountered some difficulties in the management process, one of which is data collection.

The intelligent power sensor can just take on the perception function in the smart management system. Sensors seem to be ordinary electronic components, but in fact they are an indispensable sensory organ in the field of artificial intelligence. Based on advanced Internet of Things technology, combined with more than 20 years of experience in electronic component manufacturing and the difficulties encountered by current enterprises in production management, Zhejiang Yongtailong(YTL) independently developed the "SSGo Intelligent Power Sensor-Equipment Intelligent Joint Control System".

Yongtailong SSGo power sensor (application system-SSGo equipment intelligent joint control system): It integrates information collection, real-time monitoring, analysis and prediction, safety alarm, energy consumption monitoring, and remote control. It can be widely used in various electromechanical equipment and can be effective realize intelligent interconnection, safety prevention and control, fault prediction, intelligent management, energy saving and consumption reduction. It can be widely used in all kinds of electrical equipment, such as: integrated switch cabinets, CNC machine tools, engines, air compressors, refrigerators, frequency converters, power distribution rooms, central air conditioners, water pumps, fans, charging piles, etc. It can be widely used as intelligent hardware in system integration fields such as electricity operation and maintenance, security monitoring, industrial automation, and energy-saving management.

Business Process

SSGo smart power sensor collects various power data of electrical equipment in real time, uploads it to the cloud through WIFI, RS485 and other communication means, stores, organizes, analyzes, and presents all data on the PC through the application system for real-time monitoring of equipment operating status data, Safety warning prompts and support for reverse control to realize effective remote intelligent management.

System functions

Real-time monitoring: real-time collection and monitoring of equipment operation harmonics, starting current, current, voltage, power factor, power, temperature and other parameters, and visually display them;

Analysis and prediction: historical data storage, effective analysis and early warning of equipment performance, operating status, and operating trends, predict potential failures, provide technical support for improving the efficiency of operation and maintenance;

Security alarm: Intelligent calculation, handling of overload, leakage, over temperature, ignition abnormality and failure, real-time alarm, automatic danger cut off, prevent trouble before it happens;

Energy consumption monitoring: real-time monitoring of various power consumption and efficiency parameters such as power, active power, reactive power, and power factor of each device, and real-time monitoring of energy consumption;

Remote management and control: networking and online, supporting remote on-off, realizing remote management and saving manpower.

System advantages

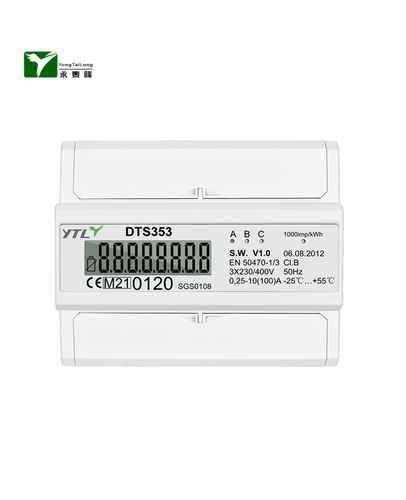

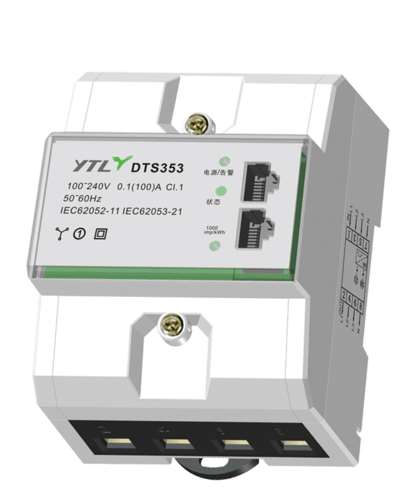

Wide range of applications: Universally used for AC and DC electrical equipment, the maximum current can reach 100A; suitable for various application scenarios, compatible with various terminal electrical equipment;

Convenient installation: Din-rail installation, width is only 18mm;

Accurate measurement: measurement accuracy Class 1.0;

Secondary development: Provide a secondary development interface, users can carry out personalized function expansion and system integration according to their actual needs;

Multiple communication: Support RS-485, WIFI multiple communication methods;

High cost performance: Realize the intelligent and networked equipment monitoring at low cost. Effectively improve the added value of equipment.

English

English 中文简体

中文简体

-1.jpg?imageView2/2/w/500/h/500/format/png/q/100)

.jpg?imageView2/2/w/500/h/500/format/png/q/100)